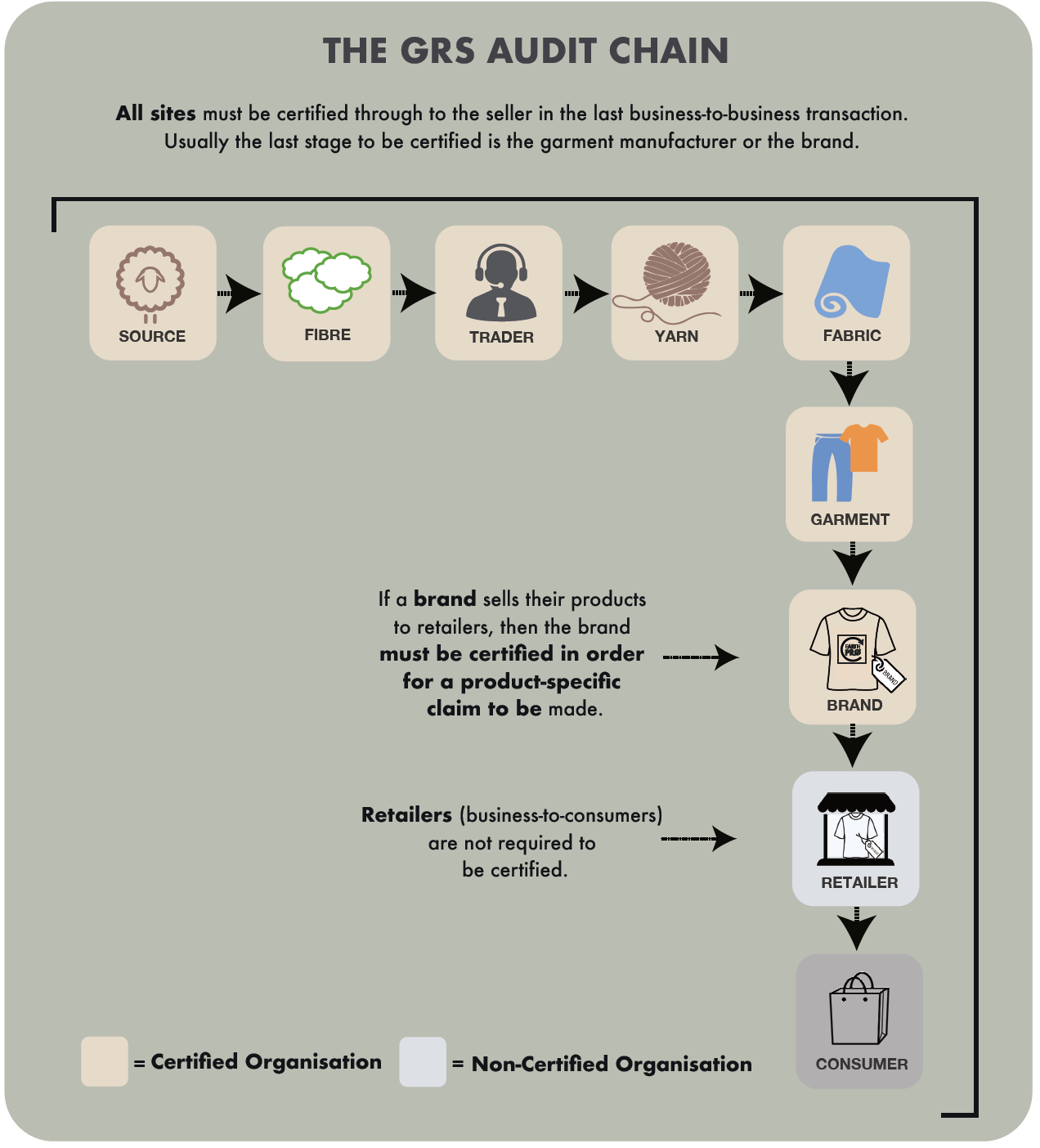

The traceability system tracks the entire journey of raw materials, from source to the final product. This process includes careful documentation, volume reconciliations, and the segregation of materials and products throughout the supply chain. These practices not only ensure transparency but also uphold ethical sourcing and regulatory compliance, key factors for responsible procurement decisions. Our traceability system ensures that every step of the supply chain is transparent and verifiable, providing accurate, certified information on the fibre content of our products.

With ØRN’s certified workwear, businesses can confidently meet a company's sustainability goals. Our traceability allows you to demonstrate to internal stakeholders and clients alike that the workwear procured meets the highest standards of ethical and sustainable production.

We help businesses incorporate these sustainable practices into their sourcing strategies by showcasing our strong sustainability credentials. Our commitment to full traceability and transparency is central to everything we do. We partner with workwear procurement managers, distributors, and supply chain leaders across the UK, offering a reliable solution for companies seeking a sustainable workwear provider. Whether your goal is to increase the use of recycled materials or reduce the environmental impact of textile production, ØRN has the certifications and audit trail to meet your requirements and support your next project with confidence.

ØRN are ideally placed and already committed to the most crucial frameworks within the textile industry, demonstrating that ØRN are leaders in sustainable workwear, tracking and tracing recycled material from source to final product.

Get in touch to find out more

CONTACT US

DISTRIBUTOR ZONE

DISTRIBUTOR ZONE